Insulate gaps, cracks and smaller spaces with our new aerosol version

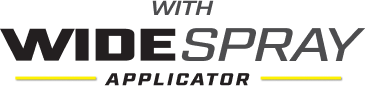

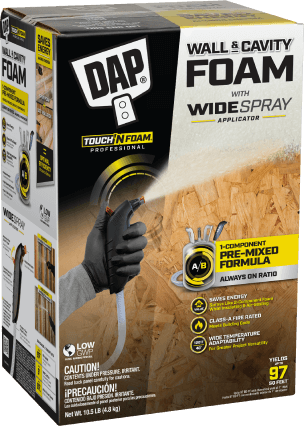

Always on Ratio Ready to Use

One Hose, One Canister, One Applicator

A proprietary technology that bridges the gap between 1-Component and 2-Component spray foam by combining a unique formulation with an innovative applicator for insulating projects.

Performance Where it Matters Most

Insulating and air sealing simplified

Saving on energy costs and improving the comfort of a home is now easier than ever. Wall & Cavity Foam is a first-of-its kind, patent pending wide spray applicator and pre-mixed formula that, like a 2-Component spray foam, air seals and insulates with ultimate spray control. Save up to 30% on energy costs by simply spraying a thin layer of Wall & Cavity Foam before installing fiberglass insulation.

Rim Joists

Tackle hard-to-reach areas like rim joists with easier portability, wide spray applicator and an 8' hose

Wall Cavities

Ideal for new additions or renovations when drywall is removed - add value and energy savings to a variety of spaces

Attics

With a wider temperature install range, tackle attic spaces with confidence and extended tack-free time for any needed corrections

FLASH AND BATT

Spray Foam + Fiberglass = Maximum Savings

Urethane foam use may be restricted or prohibited in certain areas. It is the responsibility of the user to ensure that both the foam and application process are in compliance with local building codes covering the use of cellular plastic or urethane foam. DAP Global Inc. assumes no responsibility for foam that has been applied and later found to be non-compliant.

See our productsBuy it today

EXPERIENCE the DAP Difference

Saves Energy

Performs & Sprays Like 2-component Foam Kits. Aged R- Value of 4.1 at 1” thickness

MOISTURE BARRIER

Closed Cell Formulation Helps Keep Unwanted Moisture Out

Class-A Fire Rated

Meets Building Code

Wide Temperature Adaptability

For Greater Project Versatility

* Theoretical yield in board feet (12"x12"x1")

Actual output can be affected by several factors including temperature, humidity & blowing agent loss. The theoretical yield has become an industry standard for identifying certain sizes of spray foam kits. The calculation is based upon ideal conditions, does not include blowing agent loss, and may vary according to application method or environmental factors

TRY Wall & Cavity Foam ON YOUR NEXT PROJECT